No products in the cart.

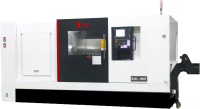

| ITEM | BML-600T | C-axis | |||

| Capacity | Swing over bed | Ø600 | |||

| Swing oversaddle | Ø450 | ||||

| Distance between centers | STD:744(A2-6);OPT:734(A2-8) | ||||

| Max machining dia. | Ø420 | Ø340 | |||

| Max. machining length | STD: 475 (8″); OPT: 485(10″) | BMT65: STD: 450 (8″); OPT: 440 (10″)VDI40: STD: 475 (8″); OPT: 465 (10″) | |||

| Slant angle of bed | 30° | ||||

| Travels | X-axis | 230(210+20) | 218(170+48) | ||

| Y-axis | – | ||||

| Z-axis | 600 | ||||

| C-axis | – | 360°(0.001°) | |||

| W-axis | 450 | ||||

| Spindle | Spindle speeds | STD: 50~4,500(A2-6);OPT: 50-3,500(A2-8) | |||

| Spindle nose | STD: A2-6: OPT: A2-8, buit-in spindle A2-6 | ||||

| Spindle bore dia. | STD:Ø62(A2-6); OPT:Ø86 (A2-8) | ||||

| Front bearing inner dia. | STD:Ø100(A2-6);OPT: Ø120(A2-8) | ||||

| Draw.bar dia | STD:Ø52;OPT: Ø75 | ||||

| Chuck | Chuck diameter | STD: 8″ +6”(W); OPT:10″ +6”(W) | |||

| Turret | Type | Hydraulic | Live-tooling | ||

| Station | STD:10;OPT:12 | STD:12 | |||

| Model | LS-240 | TBMR200/12DX (Long) | |||

| Square tool shank | 25 | 25 | |||

| Boring bar shank diameter | Ø40 | Ø40 | |||

| Iindexing time | LS-240: 1.4(8T),1.6(10T),1.7(12T) 0.73 | 0.73 | |||

| Live-tooling | Spindle speeds | – | 50-4000 | ||

| Feedrate | Rapid traverse | X: 16, Z: 20, W: 16, C: 200 rpm | |||

| Tail stock | Type | – | |||

| Quill diameter | – | ||||

| Quill bore taper | – | ||||

| Quill travel | – | ||||

| Tailstock travel | – | ||||

| Motors | Main spindle | STD: a30ip/6,000(15/18.5);OPT: a22ip/ (11/15 kW) | |||

| Sub-spindle | a6 5.5/7.5 | ||||

| Live-tool | – | a3/10,000(3.7/5.5) | |||

| X/Z-axis servo motor | X: a12 3.0, Z: a12 3.0, W: a12 3.0 | ||||

| hydraulic oil pump | 1.5 | ||||

| Chip conveyor | 0.2 | ||||

| Coolant pump | 0.8 | ||||

| Accuracy | positioning | ±0.005 | |||

| Repeatability | ±0.004 | ||||

| Power | Requirements | 380-415/220V30KVA | |||

| Machinesize | Height | 186 | |||

| Floor space (Lx W) | 441*214 | ||||

| Packing (w/conveyor) | 402*229*212 | ||||

| Net weight (w/conveyor) | 5990 | ||||

| Gross weight (w/conveyor) | 6328 | ||||

Reviews

There are no reviews yet.